科学方法

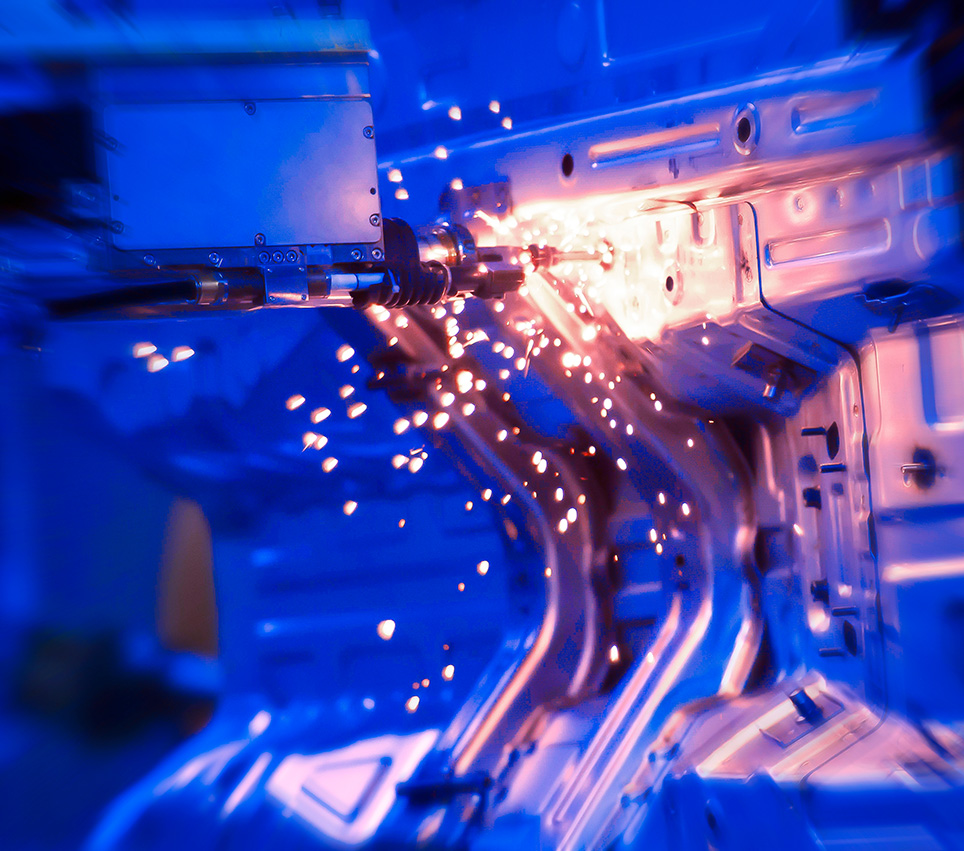

DoE for best suitable solder joint

DOE is a method for improving technological processes after it is proved that they are under control. For example; solder joint voiding is a phenomenon that causes empty spaces or voids to occur within the joint. Solder joint voiding often occurs on BGAs and larger pads. Voids are related to flux that’s entrapped in the joint, as well as paste oxidation. A large number of voids will reduce the soldering joint’s reliability. DBG is continuously monitoring and testing the preheat temperature, cooling speed, and different PCB materials to improve the thermo-mechanical reliability of the solder joints. The only way to produce top quality products for major global players.

Service detail

eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad minima veniam

寻找最合适的工艺